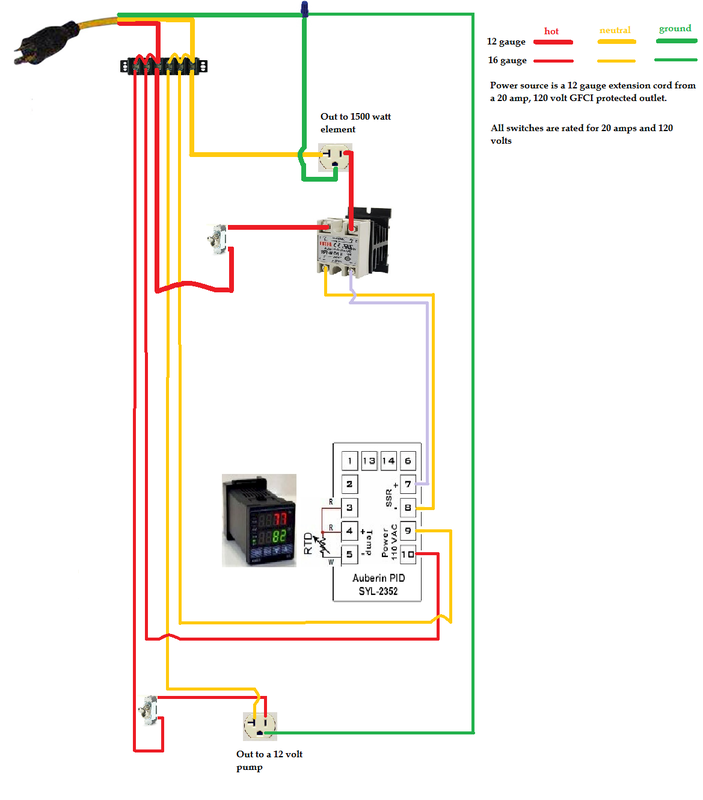

Anyways, this is pretty basic. Power comes from a 20 amp 110 volt GCFI outlet in the kitchen through an extension cord with 12 gauge wire. GCFI means that the outlet is protected and will switch off if something goes wrong and I needed the 12 gauge wire to care the amount of amps required for this. The cord goes into the box where I jump it through the terminal block to wire up everything I need. There will be two switches and two outlets controlling the power to the pump and the heating element. The switch to the element is needed so that it won't turn on whenever I plug in the control box which protects against dry firing which would ruin the element. The switch and outlet for the pump is really just a convenience and I debated including it or just plugging it into the wall but decided it would be handy. The PID, which is basically the controller of the whole operation, will always be on. It will relay through the SSR when to turn on the heating element and when to turn it off to maintain mash temperatures and a boil. The SSR is needed because the PID doesn't actually supply enough power for a heating element so the main power needs to be run through there.

Brew Kettle

7.5 Gallon Stainless Steel Kettle: 13 ½” high, 123/4” wide: $70

http://www.midwestsupplies.com/stainless-steel-kettle-with-handles-and-lid-7-5-gallon.html

Ball valve and diptube

½” SS Ball Valve: $21

http://www.midwestsupplies.com/stainless-steel-ball-valve.html

90* ½” SS Elbow for dip tube: $10

http://www.midwestsupplies.com/1-2-stainless-steel-female-npt-90-degree-elbow.html

Weldless Thermabob Adapter: $9

http://www.midwestsupplies.com/weld-b-gone-thermabob-adapter.html

RTD and attachment

Liquid Tight RTD Sensor: $35

http://www.auberins.com/index.php?main_page=product_info&cPath=20_15&products_id=246

Weldless Thermabob Adapter: $9

http://www.midwestsupplies.com/weld-b-gone-thermabob-adapter.html

Element and Attachments

Camco 1500W Screw in element: $9

http://www.amazon.com/Camco-02143-1500-Screw-Element/dp/B0006IX89Q/ref=sr_1_4?ie=UTF8&qid=1355153326&sr=8-4&keywords=120v+water+heating+element

1” SS Locknut: $6.5

http://www.amazon.com/gp/product/B003GXF5EO/ref=oh_details_o00_s00_i00

Plug: $4

http://www.homedepot.com/buy/leviton-15-amp-125-volt-rubber-grounding-plug-r60-515pr-000.html#.UO4SaG8SffI

1 ¼” x 1 ¼” rubber coupling: $5.5

http://www.homedepot.com/h_d1/N-5yc1v/R-100055392/h_d2/ProductDisplay?catalogId=10053&langId=-1&keyword=coupling&storeId=10051#.UO4S7G8SffI

Pump and recirculation return

SS Pump: $75

http://www.ussolarpumps.com/onlinestore/index.php?main_page=product_info&cPath=1_22&products_id=32½”

SS Locknut: $4

http://www.midwestsupplies.com/1-2-female-stainless-lock-nut.html

½” SS MPT x ½” Barb: $7

http://www.midwestsupplies.com/1-2-mpt-x-1-2-barb-stainless.html

½” Silicone Tubing: $2.99 per foot

http://www.midwestsupplies.com/1-2-silicone-silcon-hose-per-foot.html

½” SS Tubing Clamp: $2

http://www.midwestsupplies.com/1-2-stainless-steel-tubing-clamp.html

(3) Blichmann Quick Disconnects: $14

http://www.midwestsupplies.com/blichmann-quickconnectors-1-2-npt-x-1-2-id-hose.html

Shirron Plate Chiller

http://www.midwestsupplies.com/shirron-economy-counterflow-chiller.html

Control Box: Controls mash temp, power to the heating element and the pump

Project Box (really just a plastic storage box): $4

http://www.target.com/p/sterilite-clip-box-set-of-4-green-medium/-/A-13487783?reco=Rec|pdp|13487783|ClickCP|item_page.vertical_1&lnk=Rec|pdp|ClickCP|item_page.vertical_1

PID, SSR, Heatsink

PID: SYL 2352: $45

http://www.auberins.com/index.php?main_page=product_info&cPath=1&products_id=3

40A SSR and Heatsink: $12

http://www.amazon.com/DC-AC-Solid-State-Relay-Heatsink/dp/B005K2IXHU/ref=sr_1_sc_1?ie=UTF8&qid=1355152467&sr=8-1-spell&keywords=25A+ssr+and+heatsing

Switches and outlets

(3) Gardner Bender single pole 20 amp toggle switches: $12

http://www.homedepot.com/h_d1/N-5yc1v/R-100030219/h_d2/ProductDisplay?catalogId=10053&langId=-1&keyword=20+amp+toggle+switch&storeId=10051#specifications

15 Amp Outlet: $3

http://www.homedepot.com/h_d1/N-5yc1v/R-202066674/h_d2/ProductDisplay?catalogId=10053&langId=-1&keyword=15amp+outlet&storeId=10051&superSkuId=202887036#.UN4UIG8SffI

Extension Cord

12-3, 25’ Extension cord: $21

http://www.menards.com/main/p-1908971-c-6410.htm

Wiring Guts

Gardner Bender 22 - 10 AWG 30-Amp 600-Volt 6-Circuit Terminal Block: $6

http://www.homedepot.com/h_d1/N-5yc1v/R-202522482/h_d2/ProductDisplay?catalogId=10053&langId=-1&keyword=terminal+block&storeId=10051#.UN4JEG8SffI

16 awg wire: $10 (bought a red and black)

http://www.homedepot.com/h_d1/N-5yc1v/R-202206417/h_d2/ProductDisplay?catalogId=10053&langId=-1&keyword=16+gauge+wire&storeId=10051#.UN4RT28SffI

An assortment of spade terminals, eye terminals, butt splices, heat shrink, electrical tape and probably a few other things.

RSS Feed

RSS Feed